on this page

-

Markets

Water

Raj Chavan

VP, Sr Project Director, Henderson, NV, USA contact form+1 702 551 0298

Digital twin (DT) technology dates back to the 1960s, when NASA’s Apollo program used virtual models to simulate spaceship performance. Although not technically a digital twin, NASA’s use of mirrored systems during the Apollo 13 rescue mission laid the groundwork for the advanced DT technology that exists today. These pioneering methods demonstrated that modeling a complex system, whether in physical or digital form, was beneficial for optimization, training, and monitoring.

In the early 2000s, Michael Grieves of the University of Michigan originated the concept of the modern digital twin. Now, as sensor technology advances and the Internet of Things spreads, creating precise and dynamic digital representations of real-world assets is increasingly common in many industries. Space-age concepts have evolved into digital twins that currently are used in a variety of sectors, including aerospace, automotive, and, most recently, water and wastewater.

A Mirror Image

Fundamentally, a digital twin can be defined as a virtual depiction of a tangible entity, system, or procedure. It is akin to possessing a digital representation of the real world that mirrors it. The generation of this digital replica is facilitated by the use of real-time data from sensors, equipment, and other sources. This enables a dynamic and precise simulation of the physical equivalent.

At its core, a digital twin is a dynamic digital representation that experiences the same evolutionary process as its physical counterpart. By acting as a mediator between the tangible and virtual domains, DTs enable improved understanding, control, and optimization of complex systems.

The water sector has witnessed a growing integration of DT technology to enhance asset management, optimize operational efficiency, and guarantee adherence to regulatory requirements The sector’s imperative to confront issues such as decaying infrastructure, expanding environmental regulations, and the demand for more sustainable practices has propelled this adoption.

Challenges Addressed

The use of DT technology may revolutionize water infrastructure management. DTs have the potential to establish a more sustainable, data driven, and efficient future for the water sector by resolving pertinent challenges, providing substantial benefits, and helping utilities navigate crucial considerations. With the increasing maturity and widespread adoption of DTs, the way the sector treats and manages water resources is positioned for a paradigm shift.

Aging infrastructure. Many water and wastewater treatment facilities are dependent on aging infrastructure that is susceptible to malfunctions. By examining sensor data and historical patterns, DTs can detect impending problems such as conduit blockages and pump malfunctions, allowing water resource recovery facilities (WRRFs) to circumvent expensive downtime and repairs. Predictive maintenance based on DT insights can extend the lifespan of existing infrastructure significantly, saving the cost of premature replacements. DTs also can help facilities prioritize maintenance requirements, allocate resources effectively, and consider critical equipment in a timely manner.

Conventional processes. Traditional methods of water and effluent treatment are prone to inefficiency and a dearth of real-time optimization. DTs generate virtual environments to simulate various treatment scenarios. This conserves energy, water, and chemicals while enabling the testing and identification of the most effective treatment technologies for varying influent characteristics. DTs can analyze real-time data to adjust treatment processes dynamically in response to changing conditions, thereby increasing resource use and efficiency. They also can help optimize processes such as solids treatment procedures, thereby reducing waste production and disposal expenses.

Regulatory compliance. Complying with environmental regulations can present intricate challenges. DTs can automatically collect and document operational data, which streamlines compliance reporting with regulatory agencies. The continuous monitoring capabilities of DTs allow for early detection of potential compliance issues, which enables prompt corrective actions. By analyzing past compliance data and operational trends, DTs can identify areas with higher risk of noncompliance, allowing for proactive mitigation strategies.

Enhanced decision-making. DTs give operators access to real-time data and historical trends, which enables informed decision-making about treatment processes, maintenance, and resource allocation. They can provide predictive capabilities, allowing for planning and preparation for potential issues before they occur. DTs also create a centralized data platform for improved communication and collaboration between teams within a treatment facility.

DT Maturity Spectrum

We have partnered with The Institution of Engineering and Technology to create a digital twin maturity spectrum, which serves as a framework for assessing the degree of complexity in implementing digital twins. The spectrum typically consists of six levels with increasing complexity and functionality.

Maturity Spectrum: Digital Twins in the Water Sector

Level 0. Defining Principles

Focus: Survey; reality capture

Benefits: Basic data collection through techniques such as photogrammetry or point cloud scanning creates a static, as-built model of the physical facility

Water sector adoption: Limited

Level 1. 2D/3D Model and System Integration

Focus: Creating a basic digital representation of the physical facility and linking it to existing data such as documents, drawings, or rudimentary asset management systems

Benefits: Provides a visual reference for the facility layout and facilitates basic data organization

Water sector adoption: Early stage

Level 2. Connect Model to Persistent Data

Focus: Integrating the 2D/3D model with persistent data streams, such as historical operational data or maintenance records

Benefits: Enables basic trend analysis by combining spatial information with historical data

Water sector adoption: Growing

Level 3. Enrich With Real-Time Data

Focus: Incorporating real-time data from sensors into the DT for basic monitoring and performance analysis

Benefits: Facilitates real-time process monitoring, allows for early problem detection, and supports data-driven decision-making

Water sector adoption: Robust

Level 4. Two-Way Data Integration and Interaction

Focus: Implementing two-way data communication to enable process optimization based on data analysis and model simulations

Benefits: Enables closed-loop control systems for automated process adjustments and facilitates scenario simulations for optimizing operations

Water sector adoption: Limited, but pioneering projects exist

Level 5. Autonomous Operations and Maintenance

Focus: Creating a highly sophisticated DT capable of autonomous decision-making and self-optimization of processes with minimal human intervention

Benefits: Achieves maximum efficiency and resource optimization through automated process control and predictive maintenance

Water sector adoption: Not yet achieved in the sector; represents the aspirational future state

Water utilities in the sector are situated at different levels along the maturity spectrum. On the maturity continuum, some utilities may still be in the initial phases (Level 1 or 2), while the majority are at Level 3. A significant number of water utilities use sensor data to conduct fundamental performance analysis and monitoring.

The water sector can implement the following measures to advance along the maturity spectrum:

- Expand the incorporation of real-time data derived from sensors and additional sources into digital twins to acquire greater understanding of asset performance.

- Leverage digital twins to optimize and control asset performance in real time.

- Employ digital twins to optimize processes and performance, capitalizing on sophisticated analytics and artificial intelligence to perpetually enhance operations.

- Employ sophisticated artificial intelligence and machine learning algorithms and digital duplicates to attain complete autonomy in operations.

By adhering to these measures, utilities will be able to enhance their digital twin capabilities and realize the full potential of DT technology in terms of improving operational efficiency, enhancing asset management, and maintaining regulatory compliance.

Digital Twins in Action

WRRFs can implement a digital twin framework for predictive forecasting, process optimization, and operations and maintenance. This framework should include the following components.

- Data acquisition and integration. Collect data in real time from sensors, supervisory control and data acquisition, and other sources. Create an integrated dataset.

- Model development. Create a dynamic water system model based on collected data. Simulate system behavior using mathematical models, machine learning, and other techniques.

- Algorithms for optimization. Use algorithms to identify the optimal operating conditions for processes such as pumping, treatment, and distribution and analyze the model.

- Forecasting models. Use machine learning and statistical techniques to create forecasting models based on historical data to predict future behavior of the system.

- Scenario analysis and simulation. Use DTs to simulate different conditions, assess the impact of various operating strategies and scenarios, and optimize performance.

- Decision support system. Make informed decisions on system management and operation by creating a digital twin–based decision support system.

- Implementation. Integrate the digital twin framework with the existing infrastructure for water management and existing management and control practices.

- Monitoring and feedback loops. Continuously monitor the performance of both the digital twin system and the water systems, and update algorithms and models using monitoring feedback.

- Continuous improvement. Update the digital twin model regularly based on new insights and data.

Case Study: Beckton Sewage Treatment Works (STW)

The United Kingdom water sector has invested heavily in physical infrastructure in the 30 years since privatization to satisfy rising regulatory and customer demands. However, the utility of the future faces increasing difficulties that cannot be handled with huge capital expenditure alone.

Addressing future issues such as climate change, harsh weather, market deregulation, tighter quality compliance, enhanced resilience, and customer affordability will require new solutions and decision-making at Thames Water. It is becoming increasingly critical for WRRFs to make informed, risk-based decisions from tactical to strategic timescales. Data is abundant due to the widespread adoption of digital technology, but integrating it is the biggest hurdle to achieving the benefits of analytics and data science.

Beckton STW, which encompasses 100 ha (250 ac) and handles the waste of 3.5 million customers in London, was first built in the 1860s and has been enlarged over the subsequent 160 years to meet local demand. The current 5-year regulatory Asset Management Plan (AMP7) requires a £125 million (USD $155 million) capital investment project for the site, which has high operational and capital costs.

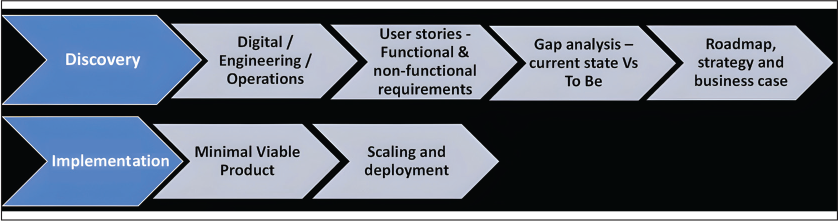

The ability to make more-informed investment decisions and optimize ongoing operational costs has shaped the vision for the project. The approach for implementing a digital twin at STW was divided into two main phases: discovery and implementation (Figure 1).

Figure 1. Delivery Approach for Digital Twin

Discovery. The discovery phase of a digital twin project aims to answer two key questions — feasibility and value delivery — before committing to implementation. In the feasibility assessment, the client vision was identified as creating a digital replica of the entire WRRF for better decision-making. Beckton STW’s strategic objectives included:

- Informing risk-based investment decisions for future maintenance plans

- Optimizing operational performance

- Enhancing asset maintenance.

The project team used agile methodology to define requirements. It held workshops to gather stakeholder input, then developed 13 key user stories — short descriptions of how DT features will deliver functionality — and grouped them under the larger epics of investment planning, operations, engineering, and maintenance strategy. They also assessed technology compatibility and measured Beckton STW’s information management (IM) maturity against water sector standards. One goal of the project was to improve IM maturity from Level 1 or 2 to Level 3.

The team performed a benefits analysis, identifying 36 benefits that they categorized into six strategic areas. They also developed a cost-benefit analysis, a business case, and implementation plan.

Implementation. The implementation phase focuses on digital and data delivery; thus, the team needs the correct combination of digital, data science, and engineering domain skills. We collaborated with Thames Water and Explore AI on Beckton STW’s implementation to guarantee the relevant capabilities were available.

Implementation begins with minimal viable product (MVP) confirmation, which allows the development team to focus on the asset system in scope, and importantly, the set of user stories that will drive the requirements. While the MVP focuses the project team, the longer-term strategy for Beckton STW requires an integrated, modular, and scalable solution that will support rolling out the solution across the wider site and the Thames Water region.

Beckton STW has three effluent streams, Activated Sludge Plants (ASPs) 2, 3, and 4. The MVP covered one stream — ASP2 — and four user stories from the operations epic.

The team identified model simulation, performance dashboards, and 3D representation as the high-level capabilities required to meet the MVP requirements. This meant the overall twin would be built up from process, spatial, and data twins. Understanding these core capabilities helped the development team focus on data collecting and integration, 3D model development, and simulation engine manufacturing at Beckton.

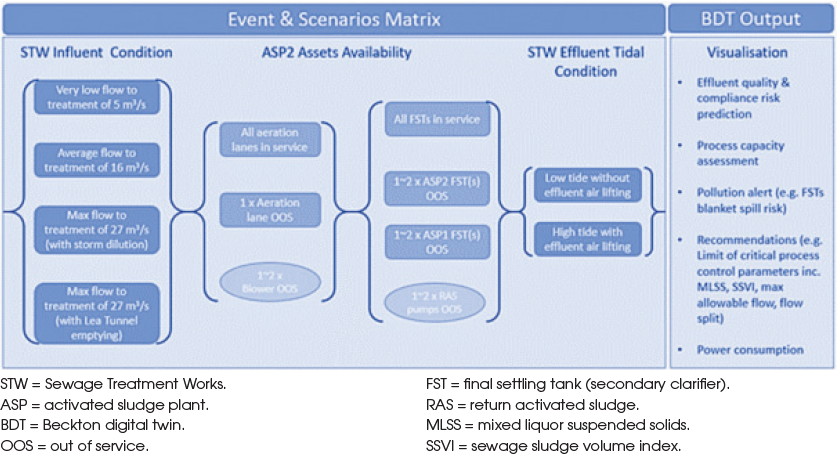

Model simulation allows the user to model many scenarios with varied flow and load levels, tidal levels, and assets in and out of service (Figure 2). The user can visualize the expected results of these models over any time span.

Figure 2. Beckton STW Digital Twin Model

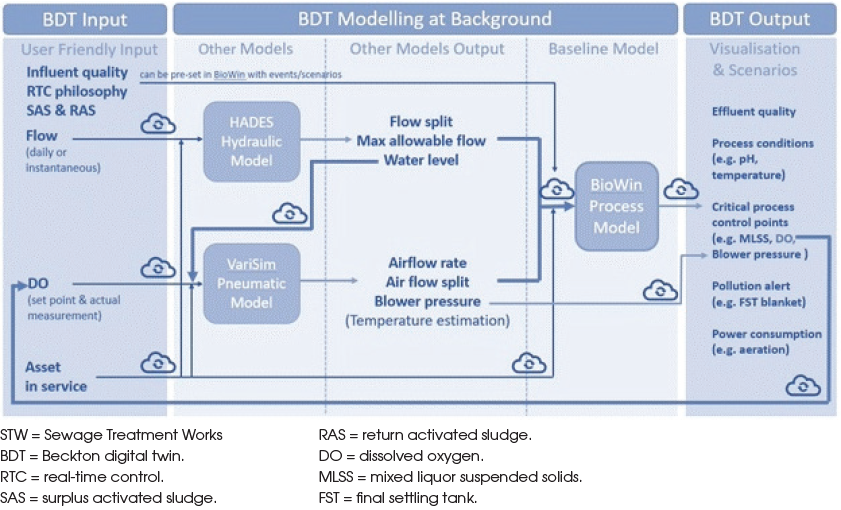

To enable model simulation, the team developed process, hydraulic, and pneumatic engineering models. These models needed vendor collaboration to run on a cloud virtual machine. Engineers had to map the intricate relationships across models to simulate situations so they could be repeated and automated in the DT integrated model (Figure 3). The team calibrated the models to make operational decisions.

Figure 3. Beckton STW Digital Twin Framework

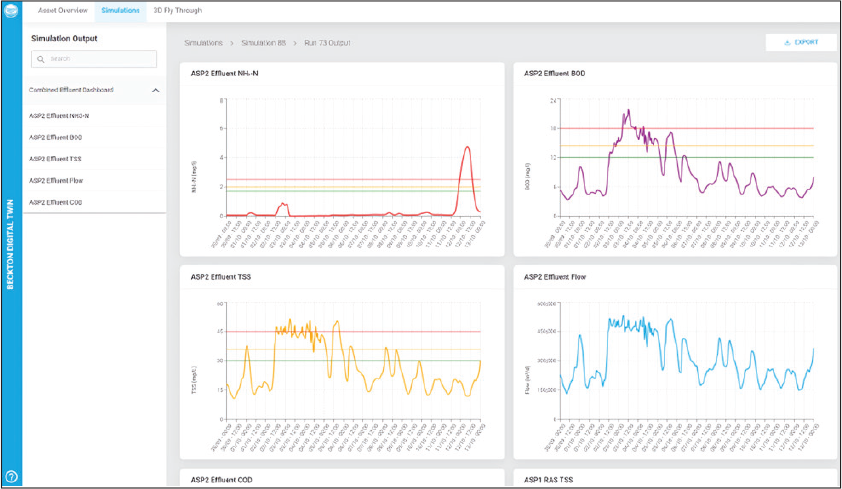

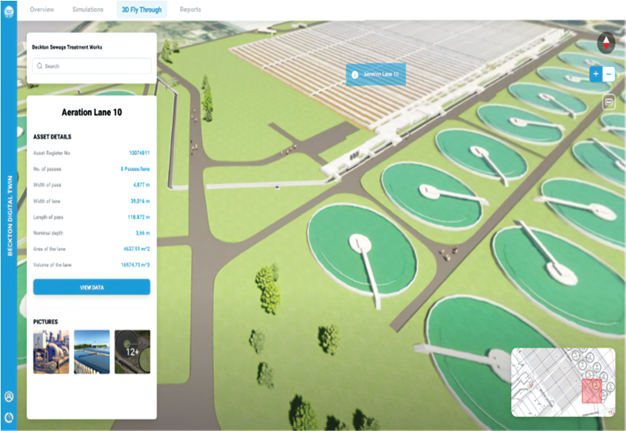

Performance dashboards display simulation predictions and facility measurements (Figure 4). The team processed drone surveys and raw data to create a 3D representation and fly-through of the ASP2 facility (Figure 5). This allows the WRRF to link data from the performance dashboard and simulations to objects in the 3D model for a more interactive view.

Figure 4. Beckton STW Digital Twin - Dashboard Example

Figure 5. Beckton STW Digital Twin - 3D Representation and Flythrough

Results. The Beckton digital twin delivered an MVP that successfully identified potential benefits in energy reduction (20% across ASP2), optimized maintenance interventions, and optimized long-term investment plans. It also provides a blueprint for Thames Water that is transferable across the region.

The Next Generation of DTs

The transformative power of digital twin technology is demonstrated by the implementation of this approach in the water sector. The work on DTs in the UK is starting to provide a holistic view on assets, processes, and performance. This allows for better informed decisions, optimized operations and enhanced asset management helping to drive forward the DT agenda and pave the way for a sustainable and efficient water sector.

A digital twin is paving the way for net-zero emissions in WRRFs. Currently, we are working with Explore AI, Siemens and Xylem to develop a WRRF Digital Twin for Severn Trent Water in Coventry, UK. They are designing the DT to help optimize the first carbon net-zero WRRF.

Building on the approach and lessons from the Beckton Project, the team is developing this DT across the whole site and incorporating new and emerging low-carbon technologies into its modeling. The DT will be deployed and embedded into the business, and the team is aiming for a Level 4 or 5 on the maturity scale, with elements of control and autonomy.

This article originally appeared in the June 2024 issue of Water Environment & Technology magazine.

Please note that you are now leaving the AtkinsRéalis website (legal name: AtkinsRéalis Group inc.) and entering a website maintained by a third party (the "External Website") and that you do so at your own risk.

AtkinsRéalis has no control over the External Website, any data or other content contained therein or any additional linked websites. The link to the External Website is provided for convenience purposes only. By clicking "Accept" you acknowledge and agree that AtkinsRéalis is not responsible, and does not accept or assume any responsibility or liability whatsoever for the data protection policy, the content, the data or the technical operation of the External Website and/or any linked websites and that AtkinsRéalis is not liable for the terms and conditions (or terms of use) of the External Website. Further, you acknowledge and agree that you assume all risks resulting from entering and/or using the External Website and/or any linked websites.

BY ENTERING THE EXTERNAL WEBSITE, YOU ALSO ACKNOWLEDGE AND AGREE THAT YOU COMPLETELY AND IRREVOCABLY WAIVE ANY AND ALL RIGHTS AND CLAIMS AGAINST ATKINSRÉALIS, AND RELEASE, DISCHARGE, INDEMNIFY AND HOLD HARMLESS ATKINSRÉALIS, ITS OFFICERS, EMPLOYEES, DIRECTORS AND AGENTS FROM ANY AND ALL LIABILITY INCLUDING BUT NOT LIMITED TO LIABILITY FOR LOSS, DAMAGES, EXPENSES AND COSTS ARISING OUT OF OR IN CONNECTION WITH ENTERING AND/OR USING THE EXTERNAL WEBSITE AND/OR ANY LINKED WEBSITES AND ANY DATA AND/OR CONTENT CONTAINED THEREIN.

Such waiver and release specifically includes, without limitation, any and all rights and claims pertaining to reliance on the data or content of the External Website, or claims pertaining to the processing of personal data, including but not limited to any rights under any applicable data protection statute. You also recognize by clicking “Accept” that the terms of this disclaimer are reasonable.

The information provided by Virtua Research cited herein is provided “as is” and “as available” without warranty of any kind. Use of any Virtua Research data is at a user’s own risk and Virtua Research disclaims any liability for use of the Virtua Research data. Although the information is obtained or compiled from reliable sources Virtua Research neither can nor does guarantee or make any representation or warranty, either express or implied, as to the accuracy, validity, sequence, timeliness, completeness or continued availability of any information or data, including third-party content, made available herein. In no event shall Virtua Research be liable for any decision made or action or inaction taken in reliance on any information or data, including third-party content. Virtua Research further explicitly disclaims, to the fullest extent permitted by applicable law, any warranty of any kind, whether express or implied, including warranties of merchantability, fitness for a particular purpose and non-infringement.

The consensus estimate provided by Virtua Research is based on estimates, forecasts and predictions made by third party financial analysts, as described above. It is not prepared based on information provided by AtkinsRéalis and can only be seen as a consensus view on AtkinsRéalis' possible future results from an outside perspective. AtkinsRéalis has not provided input on these forecasts, except by referring to past publicly disclosed information. AtkinsRéalis does not accept any responsibility for the quality or accuracy of any individual or average of forecasts or estimates. This web page contains forward-looking statements based on current assumptions and forecasts made by third parties. Various known and unknown risks, uncertainties and other factors could lead to material differences between AtkinsRéalis' actual future results, financial situation, development or performance, and the estimates given here.

Downloads

Trade releases